Non-destructive testing (NDT) is an inspection method used in many industries. The method assesses the compliance of materials, components or assemblies and detects defects hidden under the surface of the inspected materials without altering them. Non-destructive testing enables you to inspect 100% of the production output without destroying samples, thereby cutting costs related to quality control operations.

Methods exist that do not require technology, except for adapted lighting, such as visual inspection or palpation. However, these methods are limited and not 100% reliable since no one but Superman can see through the opaque matter. Fortunately, technology is coming to help industries in need, such as the oil, automotive, aerospace, marine, food, plastics and medical industries.

This article will present the main non-destructive optic-based inspection technologies, including their characteristics, capabilities and limitations.

Terahertz imaging

THz waves are located halfway between infrared and microwaves and are characterized by optical properties similar to light and propagation modes near those of electromagnetic waves. Therefore, THz waves can be focused by lenses, reflected by surfaces, detected by their electromagnetic field or emitted by antennas.

The great advantage of THz waves is that they are not harmful to the individuals who are exposed to them. To discover the main properties of terahertz waves, read the article Which Technology Should be Used to See Through Matter: Terahertz or X-rays?

The spatial resolution of THz imaging is generally in the millimetre range due to the long wavelengths involved. THz is used for in-depth inspection in real time.

Almost all non-metallic, non-water-containing materials are transparent in the THz range: concrete, brick, wood, cardboard, paper, foam, fabric, plastic, etc. Terahertz technology’s performance and safety make it popular for many applications. To find out more, read our article on applications of terahertz.

Can terahertz imaging meet your production inspection needs? To find out, send us your samples. We will test them for free in our terahertz lab and send you our test results!

Terahertz TDS (Terahertz Time-Domain Spectroscopy, THz-TDS)

Terahertz time-domain spectroscopy (THz-TDS) uses laser pulses sent into materials. It is an optical coherence tomography (OCT) that functions with THz waves. OCT is a non-contact, non-invasive imaging technique that uses laser refraction to visualize cross-sectional anatomical structures with very high accuracy.

Discover an example of OCT application in the article How to Measure Scattering Coating Thickness Effectively to Save on Resources and Energy.

The image obtained by THz-TDS imaging is accurate at depth. However, the object must be scanned systematically over its entire surface for a large image of the element to inspect. THz-TDS technology performs high-speed spot inspections (e.g. sampling the thickness of the sides of a bottle on a production line).

However, THz-TDS imaging provides a very efficient inspection solution when used in conjunction with THz imaging.

Millimetric Wave Radar

Due to its affordability, millimetric wave inspection technology is preferred when the low image resolution is not an issue. This technology can detect elements bigger than 3 millimetres. For example, the technology can be used to count bottles in a closed case to ensure that none are missing. The image resolution obtained from the millimetric radar is generally very low. However, linear millimetric radar technology is emerging that provides better performance.

X-Ray Imaging

X-rays are ionizing radiation. This makes them harmful to health. Yet X-ray imaging is used in many applications, such as in the medical and security domains.

X-rays allow us to see things on all types of materials that the human eye cannot see, such as changes in the density of the item under inspection. However, not everyone can interpret X-rays. The reading requires expert personnel and the implementation of adequate safety measures.

X-ray applications in the manufacturing industry are not very effective for soft or low-density materials such as plastics.

Transillumination

Transillumination consists of applying a light source to one side of the part under inspection and observing whether or not the light is visible through the opposite side. This technology is used in many medical applications, such as, for example, the treatment of varicose veins, certain organs or fingers.

In the manufacturing industry, conveyors can be equipped with a transillumination system for automated inspection. However, the effectiveness of transillumination of manufactured objects is limited. In some cases, the light overly diffuses in the body under inspection, making it impossible to detect small defects. For example, a bubble with a diameter of less than 1 mm in white plastic cannot be detected. In other cases, the material is too opaque for light to penetrate, such as concrete, brick or wood.

Active Thermography

Active or infrared thermography can measure the disturbances detected in thermal waves created by defects in the inspected materials, which locally affects thermal conductivity. This technology consists of heating the surface of the materials under inspection and then measuring the temperature evolution with an infrared camera.

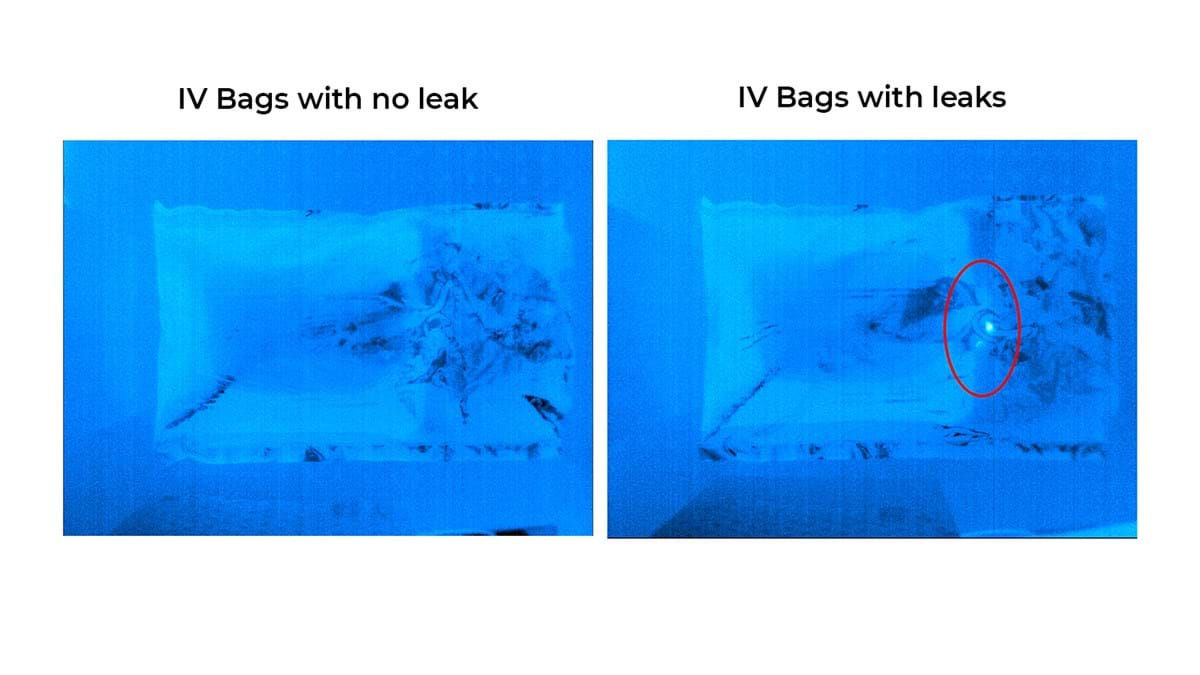

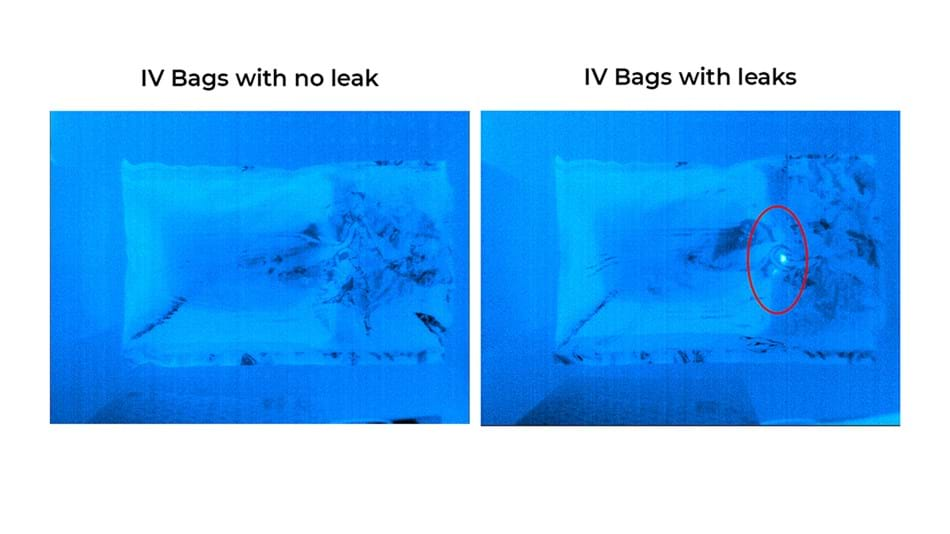

Active thermography detects liquid leaks in packaging (transparent or opaque), which is particularly interesting for certain pharmaceutical products. To find out more on this application, read the article IV Bags.

Does thermographic imaging meet your production inspection needs? To find out, contact us!

Hyperspectral Imaging

Hyperspectral technology breaks down the light reflected from the scene into many contiguous wavelength bands. Hyperspectral imaging conveys information about the surface chemistry of objects. The spectral analysis provides some identification of chemical compounds (e.g. types of plastics). We measure spectra from molecule vibrations and rotations in the 400 nm-2500 nm wavelengths. We perceive the differences if the molecules are sufficiently differentiated. There are many applications for this technology, including, for example, the detection of contaminants on products, the detection of defects, and the real-time validation of processes.

Hyperspectral imaging can detect a piece of plastic in sugar at a depth of 1 cm below the surface, where THz and X-ray are ineffective.

Does hyperspectral imaging meet your production inspection needs?

To find out, send us your samples. We will test them for free in our hyperspectral lab and send you our test results!

Conclusion

Non-destructive inspection is attractive to many industries because the technologies used are safe for health, except for X-ray inspection.

When integrated into robotic production and assembly lines, these technologies enable automated inspection and compliance of 100% of the outputs, without altering them. Non-destructive inspection allows the manufacturing industry to move toward zero defects and enables the reallocation of personnel to tasks other than inspection.

Moreover, NDT inspection avoids many returns and, consequently, limits contractual penalties and loss of contracts. This reduces quality control costs and increases performance.