Machine vision on production and packaging lines is commonly used to follow the packaging processes, product and packaging quality and/or the integrity of the assembled and packaged product.

There is already a wealth of turnkey solutions that are replacing expensive and inconsistent manual visual inspections. This also stands true for highly regulated medical and pharmaceutical industries who must comply with demanding and rigorous standards (e.g. cGMP, EU GMP, FDA Medical Device Regulation (MDR), EU MDR, ISO 11607). This is of great importance to ensure that the pharmaceutical or medical products are adequate and meet quality thresholds, but also to ensure that quality will be maintained through its shelf-life. For example, a closed container integrity testing (CCIT) strategy can ensure that the package or container itself is properly sealed to protect the sterility, maintain moisture control and prevent product tampering risks to ensure the safety of the product.

Unfortunately, while very capable and effective for many applications, standard machine vision-based inspections have limitations that result in inspection challenges that are currently unmet by off-the-shelf solutions.

Although artificial intelligence has been increasing the scope of what falls into standard machine vision by using subtle cues that may not be evident to a human observer, it is a mistake to think that artificial intelligence and its smart algorithms can magically solve any problem. You will often hear from the experts in this field: “garbage in, garbage out” referring to the case where the input data doesn’t have significant information on the feature or condition of interest, and thus no deduction can be made no matter the complexity or sophistication of the algorithm used. The type and presentation of data used for training must be carefully selected to highlight key features that the algorithm can leverage in its classification, the data must be well annotated and represent a variability representative of the real situation.

A common unmet need encountered in the industry is to detect features or defects within opaque structures, packaging or hidden by labelling. Available solutions are limited. X-Rays can go a long way; however, it is expensive to implement and come with several useability considerations including impacts on sample, operator safety, and potential impacts on adjacent equipment. A good alternative to X-Rays for many applications can be found in either THz or IR imaging. Using THz or IR wavelengths has the advantage that they are scattered less easily than visible light and they ‘see’ many materials as more transparent, yet they are not harmful or damaging to the individuals or materials that are exposed to them. To discover the main properties of terahertz waves, read the article Which Technology Should be Used to See Through Matter: Terahertz or X-rays?

THz imaging uses light with a much longer wavelength than visible or even IR light. Several materials, opaque under visible light are transparent in the THz region. That is the case for most plastics, fabrics, cardboard, paper and foam. THz imaging is thus quite useful to see through all sorts of packaging and enclosures. Additionally compared to IR or visible imaging, there is very little background THz signal in industrial environments, meaning that THz lighting will come only from the imaging setup, and will not vary based on the presence or displacement of other equipment, lighting or personnel. Discover the possibilities of THz imaging in our blog post Seven Non-Destructive Inspection Technologies for the Manufacturing Industry.

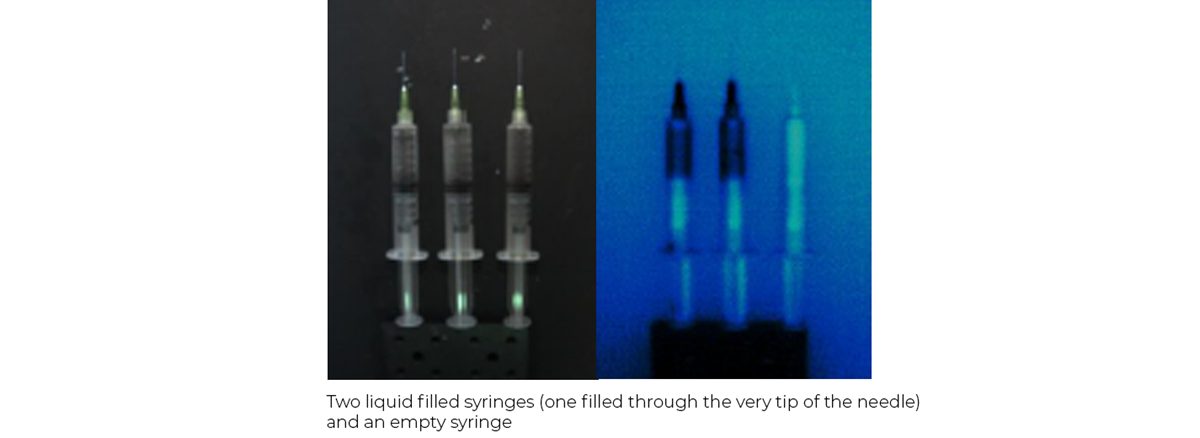

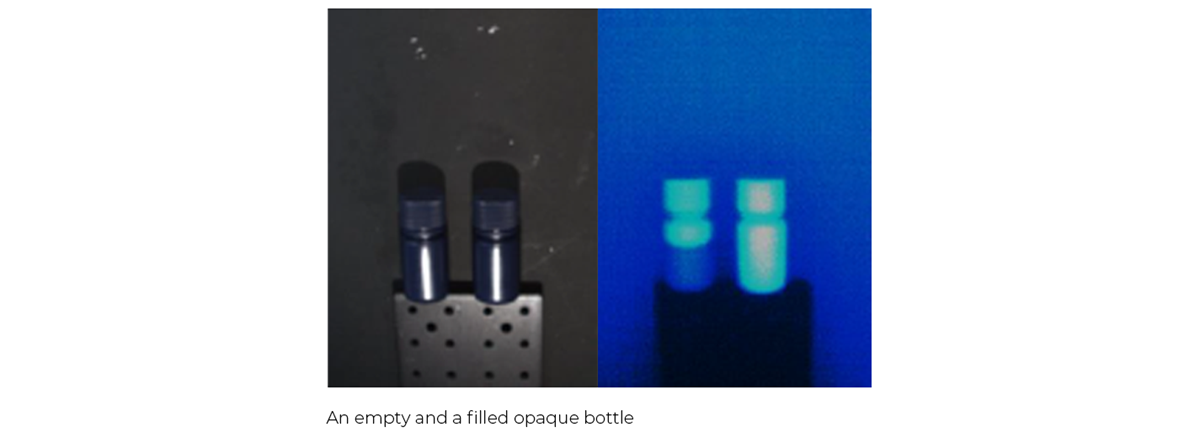

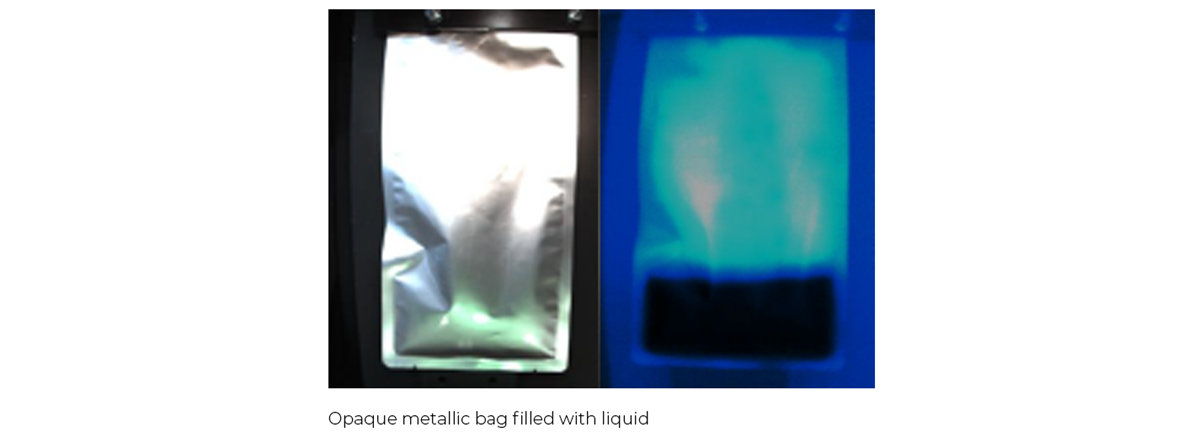

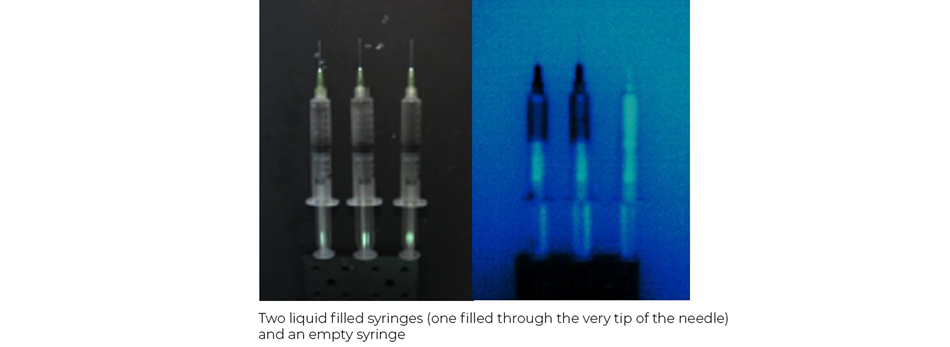

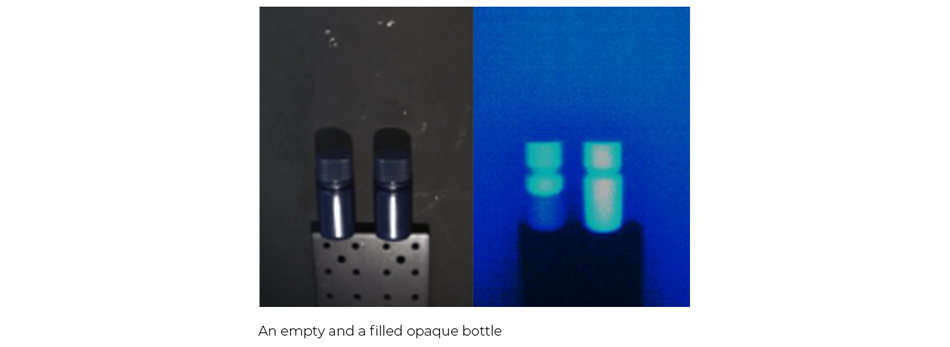

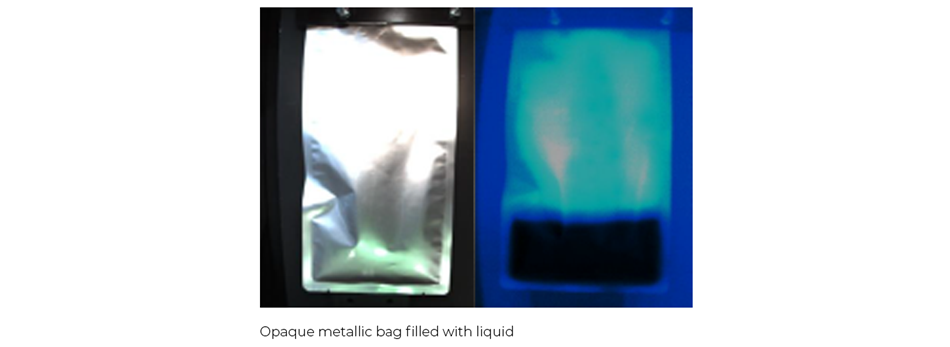

Harnessing the power of IR imaging is also quite useful to detect defects such as cracks, holes, bubbles, moisture, and more within materials. As it is the case for the THz wave, materials behave differently in IR radiation. Materials even inherently emit IR light. Differences in how they transmit, absorb, reflect and emit IR light create contrast that can be very different than what is observable with the naked eye or standard RGB cameras. Moreover, in the thermal regime using gated or dynamic imaging, information from heat dissipation within materials can help detect internal structures, layers and defects. The following images shows simple, yet helpful examples of the “see-through” capabilities with opaque containers and packages.

If your product or packaging quality control is challenging, you may find yourself in a situation where INO can help you. Our engineers and vision experts thrive on hard-to-solve challenges. We have optical system engineers and designers to optimize illumination and imaging scene to create contrast and make defects or features stands out. To complement and maximize this generated contrast, we have vision and data processing experts, capable of fusing, enhancing, and segmenting data as well as training algorithms to detect even the most subtle features.

INO is equipped with polyvalent test stations (visible, hyperspectral, IR, THz, spectrometers) to help tailor the best imaging or sensing scheme for your applications. Throw your challenge at us, let us show you what we can do.