When you need to inspect your products or control your processes, you don’t want to slow production with downtime or destructive testing. Sampling is a common but incomplete technique: defective products are highly likely to be missed, which can seriously hurt your company’s bottom line and reputation. So how do you check all your products efficiently during production to ensure that they meet your requirements?

Imagine being able to see through products as they’re moving—to identify problems quickly and fix them right away. Thinking about X-rays? Think again! Terahertz imaging can do this as well. THz allows you to see through cardboard, plastic, polyurethane foam and more—in real time and without having to stop the production line. It provides constant quality control of your assembled or packaged products.

The big advantage of terahertz is that it’s safe for employees. Unlike X-rays, the energy emitted by THz is not ionizing, so it’s harmless. THz imaging systems do not require insulation or additional protective equipment to keep your workers from being exposed to radiation.

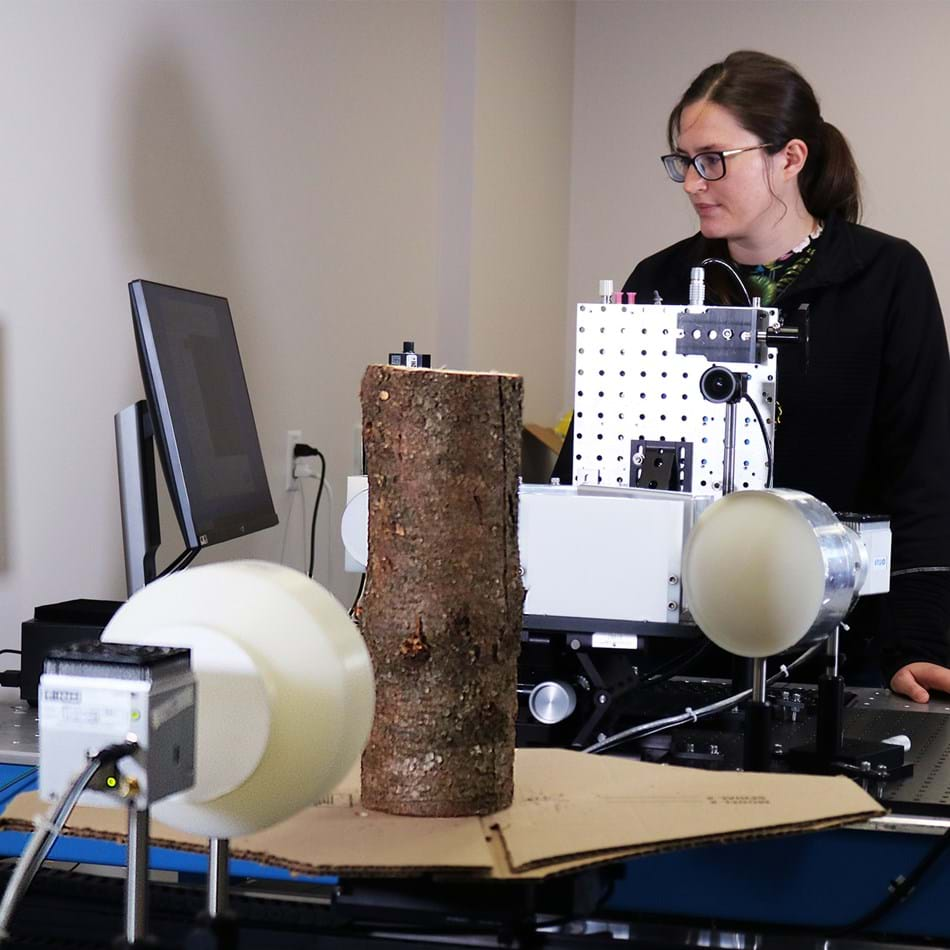

Terahertz (THz) imaging has long been an INO specialty and is both safer and less expensive to install. Over the years we’ve developed innovative solutions in various fields, including defense and security. We also have a dedicated industrial THz imaging laboratory. We can handle a wide range of samples on our controlled-motion tables to produce examples of THz imaging in transmission or reflection configurations at different wavelengths.

Whether you require a conveyor quality control system or a robotic station for your process, our team will be able to customize the technology to meet your needs. How does zero defects sound?

Solving an inspection or process control problem with terahertz is straightforward and easier than you think. Contact us to learn more about what we can do for you.