Industrialization and Scale-Up

Accelerate the transition from prototype to pilot and then commercial production with INO’s multidisciplinary expertise, certified infrastructure, and manufacturing capabilities.

✅ Reduce technical and regulatory risks with ISO 9001 and ISO 13485–compliant production.

✅ Shorten your timelines with teams and facilities dedicated to pilot manufacturing and small-batch production.

✅ Ensure quality and repeatability through documented, controlled, and traceable processes.

Industrialization at INO

encompasses all the activities required to move from a functional prototype to stable, documented pilot manufacturing that can be transferred to commercial production. This includes product engineering, production engineering, manufacturing in controlled environments, and technology transfer. INO acts as a full partner to secure quality, compliance, and scale-up.

What Results Can You Expect for Your Organization?

Whether you are a start-up, an SME, or a large enterprise, INO supports you in transforming your technology into a reliable, reproducible, and market-ready product. With its multidisciplinary teams (product engineers, process engineers, metrologists, testing & compliance specialists, technicians), INO reduces your technical and regulatory risks while securing your scale-up.

Typical Outcomes

Why Choose INO

At INO, we combine state-of-the-art facilities with hands-on expertise to help you industrialize your products.

Manufacturing

Expertise

Flexibility

Transfer

Our End-to-End Industrialization Services

Product Engineering

Product Engineering

- Obsolescence monitoring and component validation

- Design for Manufacturing, Assembly, Maintenance, and Testing (Design for X — including reliability, cost, recyclability, assembly, standards, logistics)

- Metrology: acceptance criteria, verification plans, calibration, tolerances

- FMEA (Failure Modes and Effects Analysis)

- Development of jigs and production optimization

- Configuration management and regulatory support

- Assistance with product certification

Pilot Manufacturing and Small-Batch Production

Pilot Manufacturing and Small-Batch Production

- 300 m² of reconfigurable production space

- ANSI S20.20–certified ESD environment

- ISO Class 100, 1,000, and 10,000 cleanrooms

- Rigorous quality controls, full traceability, and audited processes

Production Engineering

Production Engineering

- Supply chain strategy

- Development of production processes

- Production management

- After-sales services and warranty

- Quality assurance

Technology Transfer

Technology Transfer

- Structured process enabling successful transfers to industry (75 transfers to date)

- Deployment of production lines at the client’s site when required

- Post-transfer support to ensure operational continuity

Examples of High-Compliance Production

MEDICAL DEVICES

INO designs, develops, and delivers a first industrializable generation of medical devices, and manufactures your products for clinical and pilot trials.

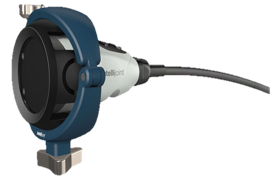

A 3D Surgical Navigation System

- FDA-certified product

- Production of more than 600 units

- Compliance with medical device requirements over several years of manufacturing.

Optoelectronic Component

- FDA-compliant product, Class III

- Production of more than 120 units

- Sourcing of high-performance component suppliers

At Intellijoint, our design process is highly collaborative. INO was a great fit for us for this reason; we were able to maintain true collaboration while leveraging INO’s incredible technical competency and state-of-the-art infrastructure and facilities. I could tell our project’s success was important to INO; they have always been flexible, accommodating, and responsive. I look forward to working with the INO team developing our next disruptive technology.

SPACE, DEFENSE, AND SECURITY

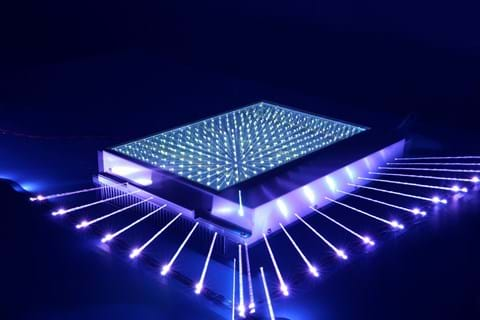

Infrared Camera Core (Space)

- Production of 20 units

Learn More About the High-Definition Infrared Space Camera Core (HDISCC)

Thanks to INO and our other partners, we're on track to fundamentally change the game in value-added Earth observation.

Examples of High-Precision and High-Stability Production

Optical Illumination Module

- Pharmaceutical industry

- Production of 40 units.

INO’s thoughtful approach that considered industrialization early in the project has delivered the stability and reliability Eikon was looking for in our drug discovery efforts.

Other Production Examples

Raman Probe Head

- Pharmaceutical, chemical, and bioprocessing industries

- Production of 280+ units.

Frequently Asked Questions

What types of products can you industrialize?

INO supports the development and manufacturing of products that include optical and photonic components requiring specialized expertise, a high level of compliance, and high precision. We manage the entire process—from engineering to pilot production—while ensuring compliance, stability, and full traceability.

What manufacturing capacity do you offer?

INO’s facilities include 300 m² of reconfigurable production space compliant with the ANSI S20.20 ESD (electrostatic discharge) standard, along with ISO Class 100, 1,000, and 10,000 cleanrooms. We manufacture pilot units and short production runs using documented, controlled, and audited processes.

Can you reduce assembly time or improve precision?

What level of quality do you guarantee?

Our processes follow ISO 9001 and ISO 13485 standards, with regular audits, full traceability, rigorous quality controls, and a culture of continuous improvement. This ensures consistent, repeatable, and compliant production over time.

To find out if we can help you and meet your needs

Do you have a question? Do you wonder how we can help you?