Realistically modeling optomechanical tolerances is a lengthy and complex process that requires a deep understanding of lens-to-mount interactions — not to mention the numerous calculations involved. COMET simplifies this critical step.

COMET directly connects your optical model to optomechanical tolerance analysis, while ensuring seamless communication between designers and engineers. With its collaborative and intuitive interface, every step of the analysis becomes faster, more accurate, and better structured.

Perform complex tolerance analyses early in the design process, easily and cost-effectively.

Access an intuitive, guided interface.

Avoid discrepancies between optical simulations and actual centration measurements.

Simulate a realistic optomechanical assembly to minimize the risk of failure due to underdesign and avoid unnecessary costs from overdesign.

Standardize communication between optical and mechanical designers to reduce errors.

- Early-Stage Applicability

This tool enables the simulation of various assembly methods early in the design process—even before mechanical modeling of the optical system begins.

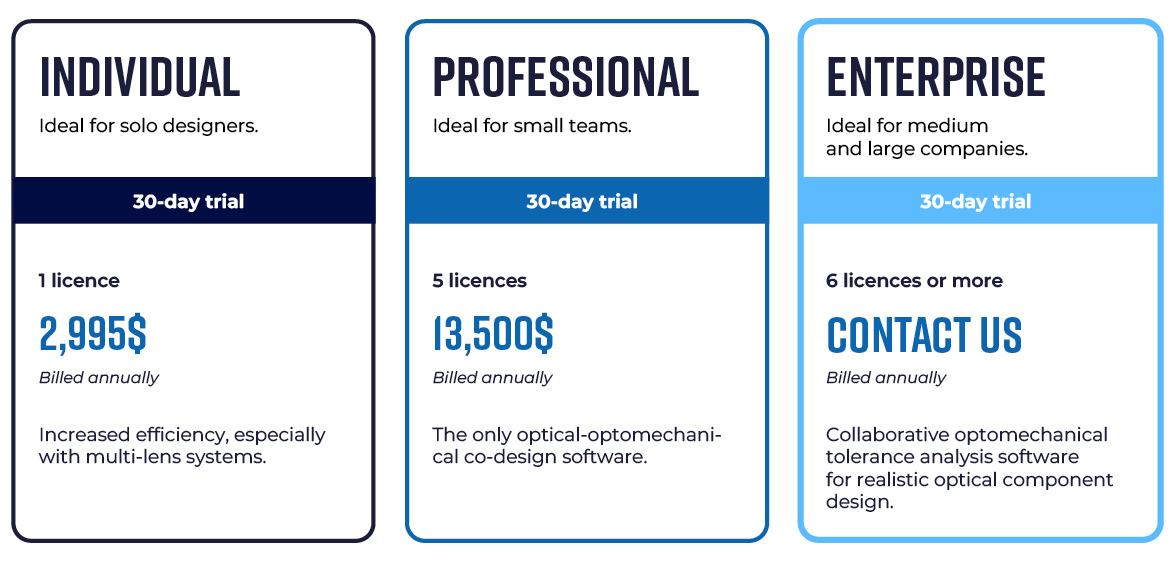

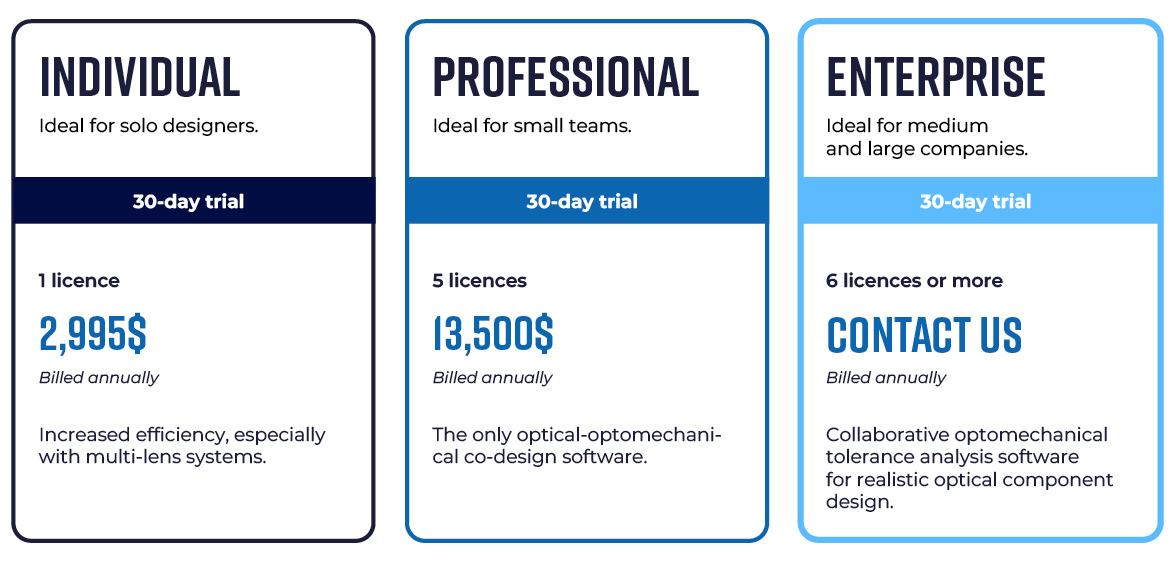

Plans and pricing

With COMET, close the gap between design and reality

Choose the COMET plan that fits your needs — whether you're an individual optical designer or part of a large engineering team.

Are you a professor or university student? Contact us for our academic pricing.

30-day money-back satisfaction guarantee

👉 START YOUR TRIAL

👉 START YOUR TRIAL

What’s included in all plans

- Full access to all COMET features

- Integration with OpticStudio files

- Guided interface for tolerance modeling

- Export to updated OpticStudio files

- Save and reload configurations

Need help choosing a plan?

Contact our team — we’ll help you find the right solution for your project.

👉 CONTACT US